Fully automated camera inspection

with state-of-the-art technology

Unparalleled in the industry at this level

Back in 2020, with a focus on the future, Technomix decided to invest in fully automated, ultra-modern camera technology for visual and dimensional inspections. This allows us to offer you maximum cost efficiency and quicker results but with the same outstanding levels of precision and reliability. Read on to find out more about what Technomix can do for you, as well as learning about how we aim to further future-proof ourselves over the coming years.

Our inspection machines identify errors that neither standard sensor systems nor the naked eye can detect.

Technomix’s fully automated optical visual inspections are intended for all companies who need quality assurance which ensures beyond any doubt that the products they manufacture match the desired specifications.

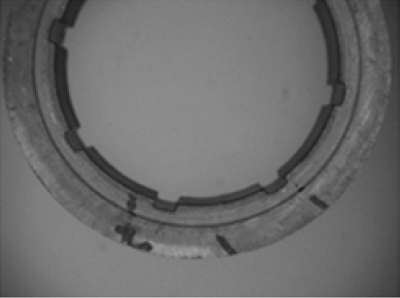

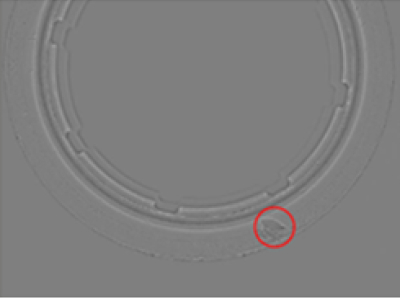

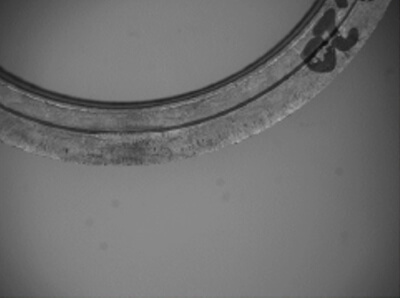

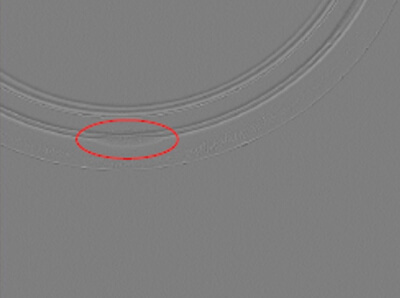

Shape from shading

Here at Technomix, we work with methods including the latest shape-from-shading technology (SFS). (Basically this is an extremely advanced 3D-measurement technique which can be used for various materials, where the majority of very subtle imperfections and form deviations in a product can be detected with very high levels of precision. This process is, of course, non-destructive, with the machine offering a variety of possible configurations to suit your requirements.)

Without any manual assistance from inspection personnel, the machines can reliably inspect up to one part per second and then automatically sort the parts into the categories “good”, “bad”, or in certain cases “undefined”. Inspection characteristics include surface condition, outline, form and colour. The superior resolution of the cameras in our inspection machines is striking when compared with the widely used standard sensor systems, and it may come as a surprise to see how many errors they can spot that would otherwise remain undetected.

Request your free, non-binding quotation today.

Every day, Technomix receives enquiries from companies that don’t want to take any chances with the quality assurance of their parts and components. Does that sound like you? Get in touch with our experts and find out for yourself how our unparalleled precision and reliable appraisals can help your business. (Fully automated camera inspection is geared towards rotationally symmetrical parts, and already covers a wide range of testable dimensions.)

The advantages of Technomix camera inspections

✅ Fully automated inspection

Suitable for all rotationally symmetrical parts and components between 5 mm and 82 mm in diameter, and 1 mm and 20 mm in height).

✅ Cost-efficient process

Particularly cost-efficient quality assurance with results that are even clearer than those provided by manual visual inspection or dimensional inspection

✅ Low personnel costs

Material tests carried out by inspection machines are generally possible without the assistance of our inspection personnel.

✅ Faster throughput

Our inspection machines can inspect up to one part per second and then fully automatically categorise inspected parts.

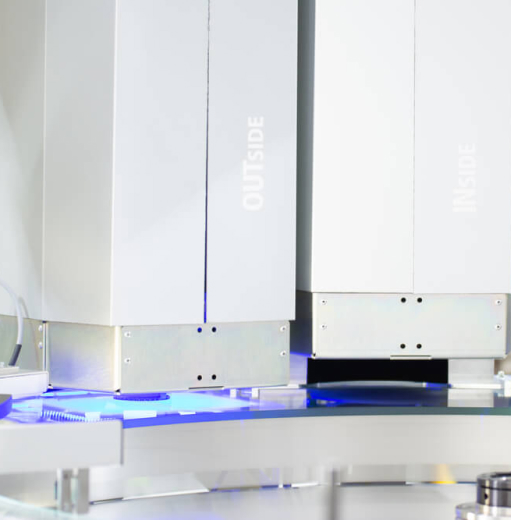

Inspection machines with state-of-the-art components

All in all, fully automated visual and dimensional inspections can provide you with a precise overall impression of your product in a very short time.

Ring test unit to conduct crack tests

High-speed double glass plate systems with turning unit

SFS sensor systems for the top side and bottom side of inspection parts

Dimension sensors to measure the external and internal diameter

Inspection parts are fed via a spiral conveyor (bulk goods) or a rotary table (individual lay parts)

Sensors for the interior and exterior of the inspection parts

More innovation every day

What makes our company different is that it never stands still. We relentlessly strive, every single day, to achieve greater levels of perfection and innovation so that you and your company can benefit from the very best solutions in quality control.

Since entering the world of fully automated camera inspection in 2020, we have been developing the technology on an ongoing basis. Our goal is always to categorically be the best partner for you when it comes to ensuring that your parts, components and products meet the highest possible quality standards.

Don’t want to take any chances with your quality control?

Reliably avoid complaints and the contract risks that go along with them by requesting a free, non-binding quotation from Technomix today. Experience our company’s discerning, innovative standards and clear processes for yourself.

Free, non-binding offers with quick response times.